Cutting-edge learning facilities

Cenovus Energy Centre

Cenovus Energy Centre

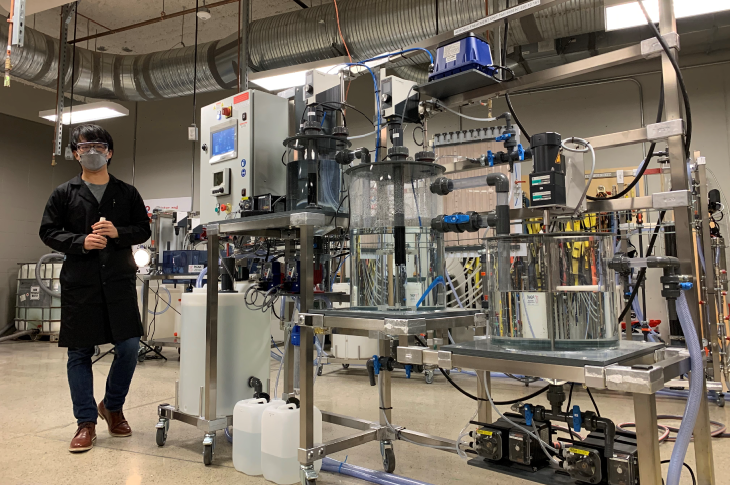

Comprised of four levels, the Cenovus Energy Centre was designed with industry input to evolve alongside technological advancements and remain relevant well into the future.

When you're a Power Engineering Technology or Process and Power Operations student, you will train in a scaled-down version of a typical steam-generating facility and equipment found in the industry. You'll get to hone your skills in a wide array of equipment, allowing you to adapt to the varying technical landscape in the industry.

The Cenovus Energy Centre is equipped with the following labs:

- Level 1: High-Pressure Steam Lab

- Level 2: Water Treatment Lab

- Level 3: Natural Gas, Internal Combustion Engine, and Air Compression Lab

- Level 4: Heating and Cooling Lab, Amine Absorption

Chemical Engineering labs

Chemical Engineering labs

As a Chemical Engineering Technology student, you will access labs where you'll learn about the properties of fluids and gases.

You also have the opportunity to train on and operate chemical engineering equipment found in the industry so you can hit the ground running when you graduate.

- Gas-absorption unit: This equipment is used in gas processing plants and refineries; it will teach you how to process raw natural gas to meet industry standards and specifications.

- Heat exchangers: You'll explore the principles of heat transfer and learn about various heat exchanger designs, their performance and how to select heat exchangers for efficient energy use.

- PVT cell: Found primarily in test labs and research facilities, the PVT cell will help you develop an understanding of the physical properties of gases required to design processing facilities. You'll also learn how pressure, volume and temperature impact the phase behaviour of a gas.

- Centrifugal pump: Centrifugal pumps provide the required energy for liquids to flow through process piping and vessels. You'll learn to evaluate the performance parameters and properties of two single-stage centrifugal pumps, which assist in designing and operating processing facilities.

- Heat loss apparatus: You'll train on this apparatus to evaluate the effectiveness of different types of insulation and learn about the effects of colour on heat loss to assess the best pipes and insulation to use in various conditions.

- Fluid circuit: Develop an understating of operation process facilities and the principles of fluid flow through piping. You'll also learn the relationships between pressure loss, pipe size, and fluid flow rate and how they impact pipe design and energy consumption.

- Distillation tower: Our continuous distillation column is equipped with instrumentation and controls typical of those found in industry, allowing you to get familiar with control logic and function.

- Aerial cooler: With applications in many process industries, you'll learn about the design parameters and operating characteristics of aerial coolers and how they're used in a wide range of industries.

- Refrigeration systems: Learn about low-temperature cooling systems used in industry and the operating principles of all the components in a typical industrial refrigeration system.

- Compressors: Compressors boost the pressure of gases in various industrial applications, such as gas transmission pipelines and refrigeration systems. You'll gain an understanding of laboratory unit operating characteristics through a bench-top, two-stage reciprocating compressor with variable speed control.

Programs

Chemical Engineering Technology

Diploma

International applicants accepted

Study all aspects of chemical engineering technology, from environmental engineering to industry safety.

Chemical Engineering Technology

Power and Process Operations

Certificate

International applicants accepted

Learn how to safely run processing equipment at oil and gas and natural gas processing facilities with classes that cover basic plant operations, safety and thermodynamics.

Power Engineering Technology

Diploma

International applicants accepted

Become a plant operator, design, research or development assistant in petroleum, petrochemicals and refining with training in power theory and thermodynamics.

Water and Wastewater Treatment Operations

Certificate

International applicants accepted

Learn the skills needed for a rewarding municipal and industrial water/wastewater system career.

Contact us

MacPhail School of Energy

KA440, Johnson-Cobbe Energy Centre, SAIT Main Campus

-

Phone - 403.284.8451

-

Phone - 403.284.8262 (fax)

Energy and Environment

Oki, Âba wathtech, Danit'ada, Tawnshi, Hello.

SAIT is located on the traditional territories of the Niitsitapi (Blackfoot) and the people of Treaty 7 which includes the Siksika, the Piikani, the Kainai, the Tsuut’ina and the Îyârhe Nakoda of Bearspaw, Chiniki and Goodstoney.

We are situated in an area the Blackfoot tribes traditionally called Moh’kinsstis, where the Bow River meets the Elbow River. We now call it the city of Calgary, which is also home to the Métis Nation of Alberta.